The quest for efficiency and sustainability in heavy machinery has led to significant technological advancements. Among these, integrating load sensing hydraulics is a pivotal innovation.

Furthermore, particularly in the performance of heavy construction equipment such as the d11 dozer. This article explores how this sophisticated d11 dozer load sensing hydraulics system has become a key factor in enhancing fuel efficiency. Moreover, as of one of the market’s most powerful and productive bulldozers.

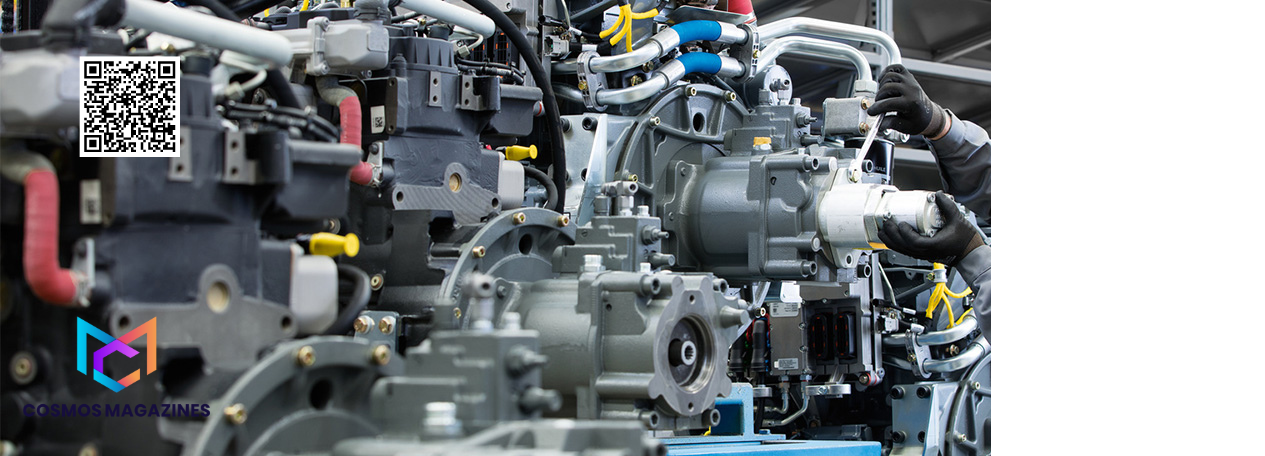

D11 Dozer Load Sensing Hydraulics

Load sensing hydraulics represent a leap forward in the intelligent management of hydraulic power. This system dynamically adjusts hydraulic flow and pressure in real time. However, based on the load requirements of the task at hand.

Unlike traditional systems that operate at a constant flow, load hydraulics allocate power only when and where it’s needed, minimizing energy wastage.

Fuel Efficiency

The primary advantage of integrating load hydraulics into the D11 dozer is a marked improvement in fuel efficiency. By optimizing hydraulic power, the system reduces the energy required to perform tasks.

Thereby lowering fuel consumption. This efficiency translates to direct cost savings on fuel and contributes to lower emissions. Moreover, aligning with global environmental conservation efforts.

Operational Precision

Load hydraulics also elevate the dozer’s operational precision. The system’s ability to adjust to the load improves the machine’s responsiveness.

Furthermore, allowing for smoother operation and greater control. This precision is particularly beneficial in tasks that require delicate handling, making this dozer versatile across various applications.

Load Sensing Hydraulics Life

The benefits of load sensing hydraulics extend to the longevity of the machinery itself. By preventing the hydraulic system from operating under constant maximum flow and pressure.

However, wear and tear on components are significantly reduced. This decreases maintenance costs and extends the service life of the dozer, enhancing its overall value proposition.

The Competitive Edge

In a market where efficiency and productivity are paramount, this dozer’s adoption of load sensing hydraulics provides a competitive edge.

This technology positions the D11 as a fuel efficiency and performance leader. Appealing to industries looking to maximize their investment in heavy machinery.

It demonstrates a commitment to innovation, setting a benchmark for future developments in the sector.

Smart Power Management

An integral feature that works hand-in-hand with load hydraulics is the smart power management system of the dozer. This intelligent feature optimizes engine output with the hydraulic demand.

In addition, ensuring the engine’s power is utilized most efficiently during operations. The dozer can achieve maximum productivity without unnecessary fuel expenditure.

Moreover, by automatically adjusting engine load based on real-time hydraulic needs. This synergy between engine performance and hydraulic demand is pivotal in reducing operational costs and enhancing fuel economy.

Load Sensing Hydraulics Controls

The equipment incorporates adaptive control systems that adjust operating parameters in response to varying work conditions.

These controls fine-tune the dozer’s performance, considering soil type, load weight, and slope gradient factors. By dynamically adjusting to the task environment, the dozer ensures optimal efficiency.

However, reduces the strain on the machine and the operator. This adaptability improves job site productivity and contributes to the machine’s longevity by preventing overexertion under challenging conditions.

Environmental Adaptability

Beyond load sensing hydraulics’ robust performance features, the dozer is designed with environmental adaptability in mind. The machine has systems that minimize its ecological footprint.

Such as low-emission engines and noise-reduction technologies. These features make the dozer suitable for operations in sensitive environments, where noise and air pollution must be minimal.

Furthermore, incorporating biodegradable hydraulic fluids and recyclable materials underscores the commitment to sustainability. However, marking this dozer as a leader in environmentally responsible heavy machinery design.

Conclusion

In conclusion, load sensing hydraulics have revolutionized the d11 dozer. Consequently, enhancing fuel efficiency, operational precision, and longevity.

This technology exemplifies how intelligent engineering can lead to tangible improvements in performance and sustainability.

As the industry continues to evolve, the principles demonstrated by the dozer’s hydraulic system will undoubtedly influence the development of future machinery. As a result, paving the way for a more efficient, sustainable, and productive era in heavy equipment.

AUTHOR (TALHA MUGHAL)

For more information, visit cosmosmagazines.com